Moving the Needle: How One Rural Congregation Electrified its Building and Secured its Future

Guest Story by Jim and Liz Fritz, Good Shepherd Lutheran Church, Decorah, Iowa

Is it possible for a small Midwestern Lutheran congregation to go from eight natural gas furnaces to eight heat pumps and create all needed energy, via solar, needed to run them in only 4 years? It is possible, and it’s happening right now!

The Background

Good Shepherd Lutheran Church of Decorah was founded in 1958 on land that was formally a sheep pasture. Plans were drawn for the current Fellowship Hall and the Education Wing. These structures were built in late 1958-early 1959, and the present Fellowship Hall was used as the Sanctuary. In 1988, Good Shepherd added a significant addition west of the existing buildings, including a large Sanctuary, offices, meeting spaces, and bathrooms.

The original building was built in 1958 and heated with fuel oil. For oil storage, a 2,000-gallon tank was buried in the yard behind the building. When natural gas became available, the switch was made with new gas furnaces (sometime in the late 1960s). These furnaces included 3-4 ton natural gas downdraft forced air furnaces. The furnaces were ducted into clay flues that lay in the soil (uninsulated!) below the slab of the entire building. By 2018 these furnaces were dead/dying, and the fuel bills were significant.

Good Shepherd, after completion of 1988 addition

In 2018 the Good Shepherd Church congregation took on an extensive remodeling project to update the 1958 HVAC system and renovate the 1958 Education Wing. The congregation decided to gut and reconfigure the Education Wing and undertake a geothermal/heat pump retrofit of the entire 1958 facility.

Jim Fritz was extensively involved in the 2019 remodeling project and, following advice from Joel Zook from Winneshiek Energy District, convinced the congregation that we should invest in a ground-source LG heat pump system using VRF (Variable Refrigerant Flow) delivery.

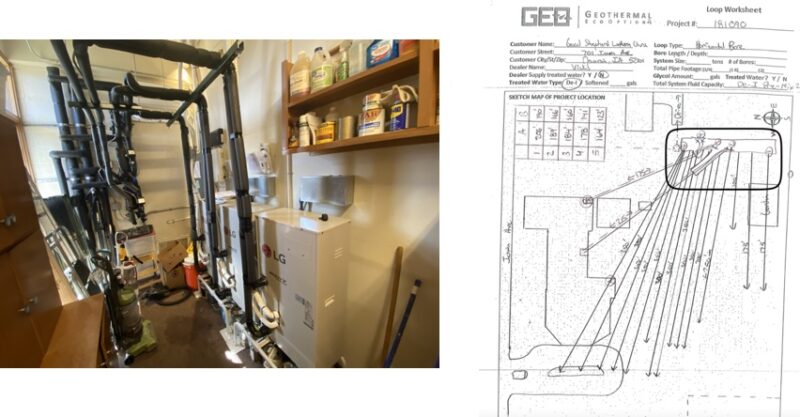

In 2019 four LG ground source heat pumps were installed in the original 1958 facilities. The original sheep pasture behind the building has 17 horizontal bore lines (approximately 10′ below grade). These geo lines enter the building and connect to four new LG geothermal heat pumps. These LG units use VRF piping (Variable Refrigerant Flow) to feed individual units in rooms, hallways, etc.

Left, ground-source heat pumps, Right, schematic of 17 horizontal ground loops

The Good Shepherd Church has some unique characteristics. It has no basement and no attic. The entire facility is on one level. Traditional forced ductwork was not an option. The size of the ductwork needed was not possible in this situation. These VRF lines (think exactly like your air conditioner lines) run through small wall chases in ceiling cavities and created architectural chases that are not restrictive like traditional forced air delivery needs.

There are other advantages to the VRF delivery system. The system is uber-efficient (more later) and easy to install lines in existing facilities. But, another advantage is individual room zoning. One room can have air conditioning while another has heat, for example, which helps increase the efficiency of the overall facility.

The Ideas

As Jim dug deeper into the facilities at Good Shepherd Church, he realized that the roof-mounted HVAC units on the 1988 Sanctuary addition were also getting past their prime efficiency. Three of the four were original to the building, and yearly service repair costs were not inconsequential. Additionally, they were an eyesore on the roof at the front of the building. He knew it was only a matter of time before there would be failures.

During this realization, Jim started dreaming about better utilization of an outdoor space directly south of the existing Education Wing and Fellowship Hall. That area was grass and had several large Maple trees. There was another existing and significant problem, as this was the space were the water was being dumped from the facilities’ flat roofs. This eventually killed the trees and was a concern for the building foundation. The questions included, how can that space replace our furnaces? He had ideas, but the question was: How to implement them?

The Solution

The solution for this project came from many conversations. Jim and Liz Fritz worked with local mentors Larry Grimstad, Andy Johnson, Joel Zook, Jim Martin-Schramm, Amy Bouska, and others to brainstorm and dream about the possibilities for this project. They worked to create and develop a business plan forming an LLC called Mission Green LLC (a mission with a company). Would a carbon-neutral project fit in with their ideas? Can you grow a business using a Power Purchase Agreement (PPA)? Could this idea/business model allow Good Shepherd to lower energy bills and their carbon footprint? Could this include some of the ideas for the outdoor space?

The result of these conversations and questions was a proposal from Mission Green to enable a Carbon Neutral Project for Good Shepherd. Mission Green would create a business relationship with the Good Shepherd congregation, whereas we would:

- Sell them the electricity at lower fixed costs through a PPA.

- Eliminate their use of carbon-based fuels by installing and leasing heat pumps, while removing the eyesores on the roof.

- Provide an opportunity to fix the water problems of the outdoor space (French drain).

- Update/upgrade all service entrances to the entire facility.

- Provide solar panels for rooftop installation (21 kW, 52 bi-facial).

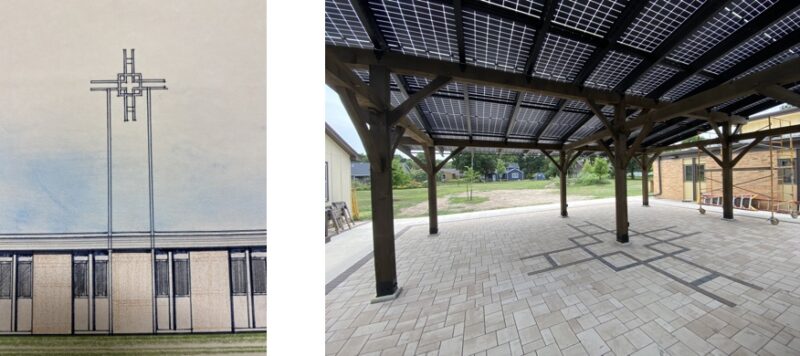

- Provide a 37’x37′ solar canopy (27 kW, 50 bi-facial panels) with a waterproof racking system on a Douglas Fir post and beam pergola.

- Install a permeable paver courtyard directly over the French drain, with sound and light amenities.

These contracts dictated Mission Green would receive monthly payments from the PPA for kWh generation and heat pump lease payments from Good Shepherd for six years. Mission Green will monitor the output/usage of the Good Shepherd facilities. At the end of the PPA, the congregation will buy out the PPA solar portion of the project at fair market value. After the buyout, Good Shepherd will own all the infrastructure to heat/cool/illuminate the entire facility, all on-site.

The Mission Green proposal was approved at a Congregational Meeting on June 5, 2022, when a vote was taken. The proposal was approved by 99-4.

Mission Green Website, missiongreen.llc

Moving Forward

Supply chain issues completely stalled the project into late 2022. Finally, the new service entrance and the rooftop solar (21 kW, 52 panels), on the white EPDM roof of the Education Wing, installed in late October 2022.

21kW Rooftop solar installation, October 2022

Three new 5-ton LG air-to-air heat pumps were installed in the 1988 addition in late December 2022 and early January 2023. They were officially online by January 15, 2023. The installation also included a 15 kW resistive electric heat backup unit, an industrial steam humidifying unit, and a high-end air filter utilizing UV, electrostatic, and filtration. Every room is individually zoned. One week after the switch to the new air-to-air heat pumps, there were a few nights of -17 below. At 7 am the following day, the facility still registered at the set point of 67 degrees.

Heat pumps are an important element in this project. The four heat pumps installed in the 1958 building are 450% efficient (due to the geothermal factor). The three 5-ton air-to-air heat pumps installed in the 1988 addition are still 350% efficient with no boring required!

Three 5-ton LG air source heat pumps serving the 1988 addition

Water Issues

The new courtyard below the solar pergola accomplished quite a bit for the project. Construction included removing the 2,000 gallon fuel oil barrel and the relocation of an outdated, unsightly Alliant Energy transformer. The congregation decided it was in the best interest of the existing structure that the water issue be dealt with at this time. The congregation voted to pay for the recommended construction of the French drain. Good Shepherd Charter member Lindsay Erdman provided the official designs for the French drain. Legacy Concrete/Finholt Construction and Pinter Landscaping did the work.

Removal of the 1958 2,000 gallon fuel oil tank

This project included excavation to a prescribed 42″ depth. Unfortunately, we couldn’t anticipate the size of the old fuel oil barrel in that location. It was buried nearly 7′ deep and roughly 15′ long, requiring filling and compacting gravel every 5″ of rise. There is approximately 200 ton of compacted, crushed stone below this courtyard.

Local craftsman, Dale Kittelson, created the Douglas Fir post and beam pergola structure.

Construction of the doug fir pergola

Mission Green installed a permeable paver courtyard above the French drain and below the post and beam solar pergola to better reflect on the bi-facial solar panels. A stylized cross, copied from the 1958 architectural drawing for the original building, was added to the courtyard’s center. Mission Green installed architectural LED lighting and an outdoor sound system. This area will become a significant new space for events at Good Shepherd while adding to the efficiency of solar production.

The permeable paver courtyard speaks to the design elements of the original 1958 church

The Solar Pergola

The racking system for the solar pergola is the real gem of the entire solar facility. It is from the Couillard Solar Foundation of Deerfield, WI. Cal Couillard, the CEO, formerly owned a large aluminum extrusion manufacturing factory. He sold it to a multi-national company and used portions of the sales receipts to establish a solar foundation that donates solar arrays to non-profits in Wisconsin. Cal developed and patented (pending) the anodized aluminum extrusion racking system that supports the pergola solar array. It is simple, super strong, elegant compared to the industry, and adaptable for various use cases.

A low interest loan from the Iowa Energy Office/IEDA was used to finance the project along with a grant from the Hammond Climate Solutions fund. Mission Green sought assistance from the Winneshiek Energy District and greenpenny.bank of Decorah. We used local contractors extensively: Decorah Electric -Joel Teslow, Vick’s Heating and Plumbing – Steve Klemme, Legacy Concrete/Finholt Construction – Seth Klotzbach, Kittleson Woodworks – Dale Kittelson, Pinter Landscaping – Shane Pinter, Reed Fitton, and Tom Bourcier. There was also a list of volunteers too long to name. THANK YOU to all!!

Carbon Neutral Project Accomplished

Good Shepherd is now 100% electric. The gas meter was removed in February 2023. The Good Shepherd Carbon Neutral Project has replaced the fossil fuel HVAC system with four geothermal heat pumps, three air-to-air heat pumps, and a mini-split unit. It can heat/air condition the entire facility using solar electricity, all created onsite. LED lighting throughout the whole campus also reduces the overall electrical needs. Other efforts by the congregation to lower their Carbon Footprint include planting over 20 trees in the campus greenspace and considering adding a prairie wildflower/pollinator garden.

Current projections indicate that the 55 kW of onsite solar will provide 99.2% of needs. Current energy needs are now being met via solar production, and Alliant Energy Corp has granted us Full Net Metering. We’ll monitor the system for 12-18 months, but our hope/goal/aim is also to be Net Zero or even Net Positive.

Once the PPA and lease are completed, the congregation can use previous energy dollars for mission dollars instead. We’re proud of our combined efforts to Move the Needle in the fight against climate change.

With new national incentives through the Inflation Reduction Act (the IRA bill), this work is eligible for a 30% tax credit. The new Act also allows non-profits to recover this credit, which wasn’t possible when Good Shepherd joined Mission Green for this project. The current national programs are the best possible “sale” of renewable energy options in our lifetimes. Now is the time to act!! Let’s move the needle!